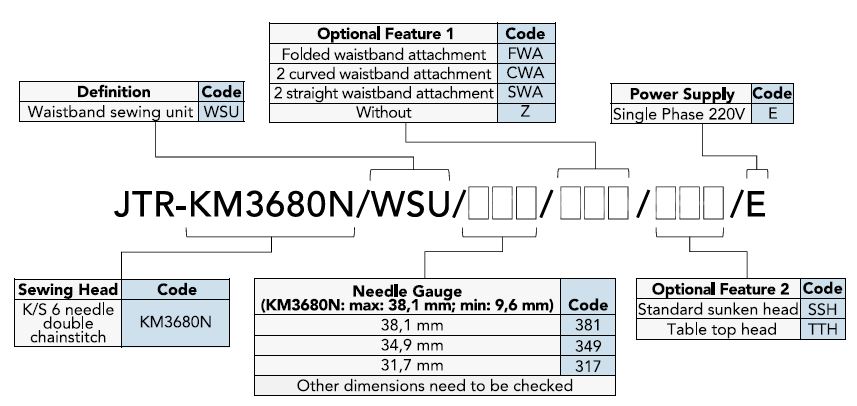

JTR-KM3680N/WSU – Waistband Sewing Unit (Double Chainstitch)

The stitch-skipping function used at the beginning and end of sewing improves workability in the sewing of waistbands.

You’re now subscribed to price tracking for this product. We’ll notify you if the price drops.

Product features

-

The machine can skip stitching at the beginning and end sewing positions, thereby reducing unstitching work in the next process

The sewing machine can skip stitching for a preset distance at the beginning and end positions in the waistband sewing process. The settings can be entered on the touch panel with speed and ease.

-

The waistband is automatically cut before the start of sewing and after finishing

The machine automatically cuts the waistband at a set position before and after sewing to reduce manual cutting work by the operator. The machine supports both straight and curved waistbands by changing the cloth puller.

-

Vertically driven cloth cutting knife controlled by a stepping motor

● Thanks to the stepping motor control, the knife pressure can be easily changed on the operation panel to suit the material, thereby preventing uneven cutting.

● Changeover between the cut-before knife and cut-after knife can be carried out on the operation panel.

● With the air gun configured in place of an air-driven knife, parts such as the knife-driving arm no longer break and fluctuations in the air pressure driving the knife no longer cause uneven cutting. The air gun consumes only one-seventh of the air consumed by a standard eyelet buttonholing machine, which eliminates the need for a high-capacity compressor. -

Separately driven right and left work clamps

The right and left work clamps are separately driven by independent air cylinders. With this mechanism, the work clamps reliably clamp materials of different thicknesses to prevent the materials from flopping.

-

Reduced power consumption in standby

In addition to reducing power consumption in standby mode (55% compared to a conventional buttonholing sewing system), the new motor control also reduces heat generation in the machine head. With its improved features, such as its wind-resistant thread path and cloth-cutting mechanism shielded from air pressure fluctuations, this machine provides consistent seam quality in any operating environment.

-

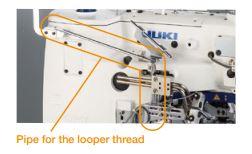

Equipped with a shield to protect the looper thread path from wind

The pipe-type thread path that comes with the machine reduces thread friction and protects the thread against the effects of wind. This thread path can be easily threaded with an accessory air gun.

-

Newly developed machine head that efficiently sews longitudinal buttonholes

● JUKI has newly developed a machine head with a shallow recess. For the efficient sewing of longitudinal buttonholing.

⁕Use MEB-3200CRS for combined use for lateral and longitudinal buttonholing.

● The machine head has a wider space under the work clamps to permit easy placement of a sewing product, thereby improving workability.

● The semi-sunken machine head promises easy placement and smooth handling of sewing products.

● The amount of material opened can be easily adjusted using the screw mounted outside the machine head. -

Direct-drive motor is adopted

The machine has adopted a direct-drive method that connects a compact AC servomotor directly to the hook-driving shaft. The quick startup and increased stopping accuracy obtained as a results guarantees outstanding responsiveness. In addition, the direct-drive motor does not use a V-belt to reduce power consumption.

-

Excellent maintainability

● The computer controlled design eliminates most of the complicated mechanisms. This dramatically improves maintainability.

● The machine head is supported by a gas-spring that makes it easy to raise for smoother cleaning and threading. -

Improvements of working environment

● Designed without a clutch mechanism or stopmotion mechanism, the machine produces no stop-motion noise.

● The machine automatically reclaims cloth chips after cloth cutting action to keep the working environment cleaner. -

Equipped with a color-tunable LED light

The machine is equipped with a color-tunable LED light that can be adjusted from daylight white to light bulb color. The LED can be adjusted to suit the sewing material and environment for improved workability.

-

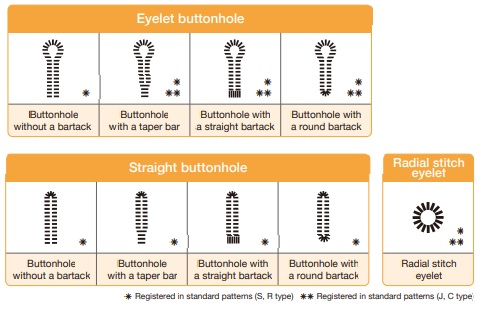

Thanks to the computer control, many different eyelet shapes and straight buttonhole shapes can be selected or established on the operation panel

The machine is provided as standard with 11 different stitching shape patterns. As many as 88 different patterns can be stored in memory and selected.

| Model name | JTR-KM3680N/WSU |

|---|---|

| Machine Head (Standard) | Kansai Special DLR-1509P |

| Motor | Direct Drive Servo |

| Max. sewing speed | 3.200 rpm |

| Capacity | 2.000 to 2.500 jeans & chinos / 9 hours |

| Daily Piece Counter | Available |

| Min. - Max. Stitch Length | 1.5 mm - 3.5 mm |

| Needle Type | TV-5 #21 |

| Needle Gauge | 1/8”-1/8”- 1”-1/8”-1/8” |

| Power Requirement / Power Consumption | Single-phase 220V-240V 50Hz / 650VA |

| Compressed Air / Air Consumption | 6 Bar - 16 L / min. |

When you place orders